To put simply, water jet (other names: blasting, waterjet, water jet cutting, pure waterjet, water-only cutting, abrasive jet) refers to the use of a jet of water under extremely high pressure to cut the material max. 195 mm thick. The table used for processing elements is 4x2m.

The table used for processing

elements is 4x2m

Material

thickness195 mm

It allows to cut large elements or several elements simultaneously using a jet of water. In case of cutting soft and thin materials, it is enough to use water only. However, as far as harder and thicker materials are concerned, it is essential to use water with an additive of abrasive agent (garnet). Water allows to “accelerate” the abrasive material to the speed similar to the speed of sound (340,3 m/s), which provides incredible precision guaranteed by the water jet technology. The garnet abrasive may be compared to sand with an exception that it is definitely much harder and has sharper edges.

Water jet is an innovative technology using a jet of water under extremely high pressure to cut all types of materials ? i.e. stone, glass, wood or plastics. The key advantage of the water jet method is the lack of heat impact on the processed material. In case of cutting soft and thin materials, it is enough to use water only. However, as far as harder and thicker materials are concerned, it is essential to use water with an additive of abrasive agent (garnet). The abrasive water jet allows to “accelerate” the abrasive material to the speed similar to the speed of sound (340,3 m/s), which provides incredible precision guaranteed by the water jet technology. The garnet abrasive may be compared to sand with an exception that it is definitely much harder and has sharper edges.

Water jet is unrivaled by any other cutting method. First of all, a jet of water may cut materials much thicker than those cut by a laser or plasma. Apart from that, the processing is characterized by better precision than in case of other methods. Additionally, the material is not subject to high temperatures as in case of thermal cutting. Therefore, the cut material is not at risk of mechanical damages, such as scratches or micro-cracks.

The abrasive jet has many advantages, of which the most important are the following:

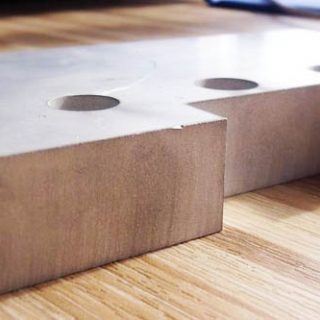

We have only high-specialized equipment ? SmartJet 2040, which allows to cut materials max.195mm thick using high pressure water jet. Our table used for processing elements is 4x2m. It allows to cut large elements or several elements simultaneously. Thanks to our specialist equipment we ensure precise cutting and a possibility of creating various, even the most complex shapes, with high quality and smooth edges.

Bearing in mind the complexity of materials and raw materials, we treat every abrasive jet service in an individual manner and execute our orders accurately, efficiently and reliably. To address the needs of our clients, we are open for any proposals and happy to share our experience.

Our company offers the abrasive waterjet services, i.e. cutting materials with a jet of water, and guarantees full professionalism, short implementation deadlines and competitive prices!

We will carry out the valuation on the basis of the following form. Please fill out all fields carefully and, where possible, attach figures in dwg, pdf, jpg or cad formats.

Form is deprecated, please contact the webmaster to upgrade this form.

Attach CAD file and we will get back to you with our valuation within 12 hours.

Only water jet may guarantee incredible precision, thanks to which it is possible to cut every, even the smallest detail. Traditional steel processing methods require final corrections, whereas the CNC technology guarantees quick and easy work with spectacular effects. With us, you can cut any type of steel ? tool, acid resistant and armored steel.

The water jet method does not cause any mechanical stress on the material surface, thus, there is no risk of deformation or hardening of the material or creation of splinters. Once the work is finished, the material surface remains smooth and uniform, which eliminates the necessity of repeated final processing. Apart from that, no significant losses of the cut material occur, which means that the material is used more efficiently. Now you can cut all non-ferrous metals and their alloys.

The art of water jet cutting helped to create many works of art, whose sight is truly breathtaking. Such effects may not be achieved using traditional methods, such as laser or plasma, since the stone is a really fragile and hard to treat raw material. This amazing accuracy of the machine using a jet of work under extremely high pressure guarantees precise reflection of a complex pattern.

| TECHNOLOGY | LASER | PLASMA | WATER JET |

|---|---|---|---|

| Cutting materials | laser beam | plasma | water jet |

| Cut materials | with a broad spectrum apart from materials with high reflection coefficients | ferrous and non-ferrous metals | all materials |

| Cutting method | hot cutting | hot cutting | cold cutting |

| non-metallic materials | no | no | yes |

| Possible application of many heads | no | limited | yes |

| Multi-layer cutting | no | no | yes |

| Composite materials | no | no | yes |

| Material hardening | yes | yes | no |

| Cutting shapes | complex | simple | complex |

| Creation of splinters | yes | yes | very limited |

| Additional processing | yes | yes | very limited |

| Loss of material | high | yes | very limited |

| Tolerance levels | 0,1 mm | 0,2-0,5 mm | 0,1-0,3 mm |

| Creation of harmful fumes | yes | yes | no |

| Possible cutting of materials covered with rust and scale | satisfactory | good | very good |

| Material thickness | <25mm | <80mm | <305 mm |

| Material deformation | yes | yes | no |