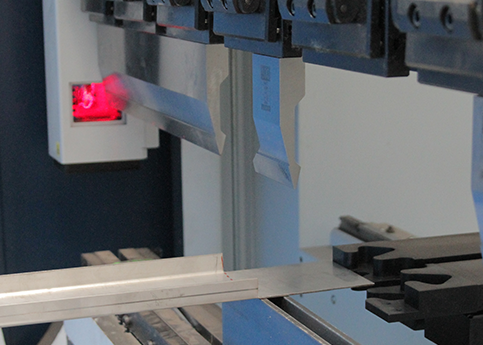

Metal sheet bending – press

The bending services are rendered using CNC brake presses designed for bending sheet metals. The processed object is bent by shear force moving downwards. The shear force is of 1700 kN. It allows to process elements 15mm thick.

length of elements subject to bending 4080mm

The bending process is possible thanks to special tools ? i.e. stamps and matrices. The choice of a given tool depends on the bending method, material, thickness and angle of the metal sheet. In case of unusual orders, it is possible to order stamps and matrices upon request. It may take longer time to implement the project.

The machine is operated via a touchscreen. The control system calculates all bending parameters. Thanks to display of the changeover plan, we may shorten set-up times and hence improve productivity of the machine.

Our machine is equipped with five-axis bumpers. The bumpers allow bending in all plains, which means that we can easily create spatial elements, e.g. funnels. Thanks to repeatable accuracy of positioning, the bending angles may be reproduced also in case of large batches.

Feel free to send us any questions you may have! We will be glad to help clear up all your doubts.

For the purpose of valuation, we need data on the type and thickness of the material as well as bending radius of the metal sheet. Additionally, we will be happy to receive a figure of the element to be bent, which will speed up the valuation process.

Metal sheet bending – a brief summary

Metal sheet bending means permanent deformation of material as a result of moment bending.

The procedure should be implemented without affecting the integrity of the material. If the value characteristic of a given material is exceeded, the bent object will be damaged. If the radius value of the metal sheet bending reaches its critical point, cracking will occur. In case of more plastic metals, this limit allows to bend much smaller radiuses. Unfortunately, the cracking of the material may cause its other defects, such as scratches, unevenness or tears.

The bent materials may be creased during compression stress. By introducing additional tensile force, we may combat this phenomenon.

Valuation

We will carry out the valuation on the basis of the following form. Please fill out all fields carefully and, where possible, attach figures in dwg, pdf, jpg or cad formats.

Form is deprecated, please contact the webmaster to upgrade this form.

Attach CAD file and we will get back to you with our valuation within 12 hours.